NODO Floor Lamp

Senior Thesis

6 Months

2024/2025

Flexible Joinery:

Assembly, Disassembly & Adaptability through Soft Craft

construction for the circular economy using a traditional fiber technique

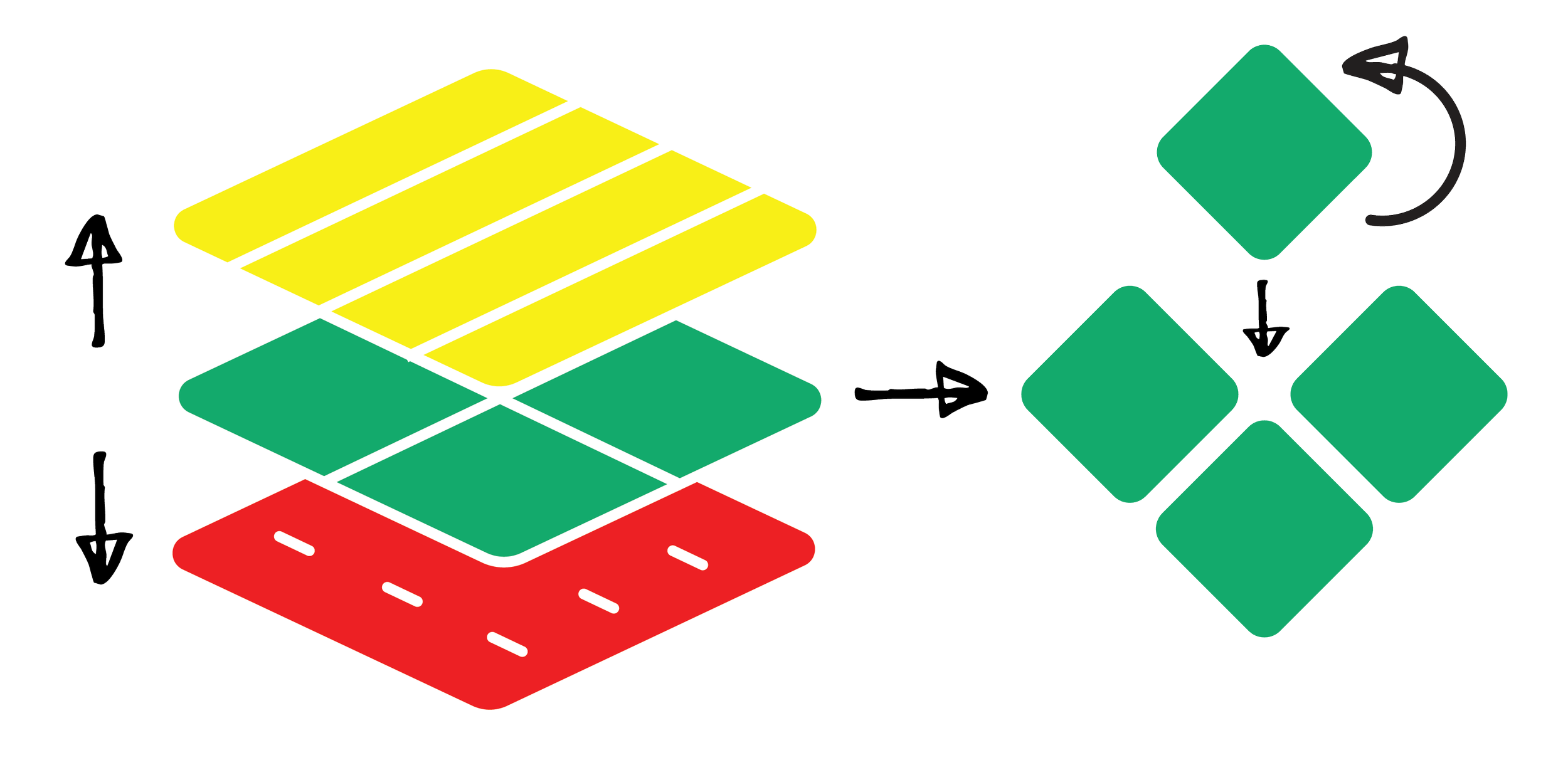

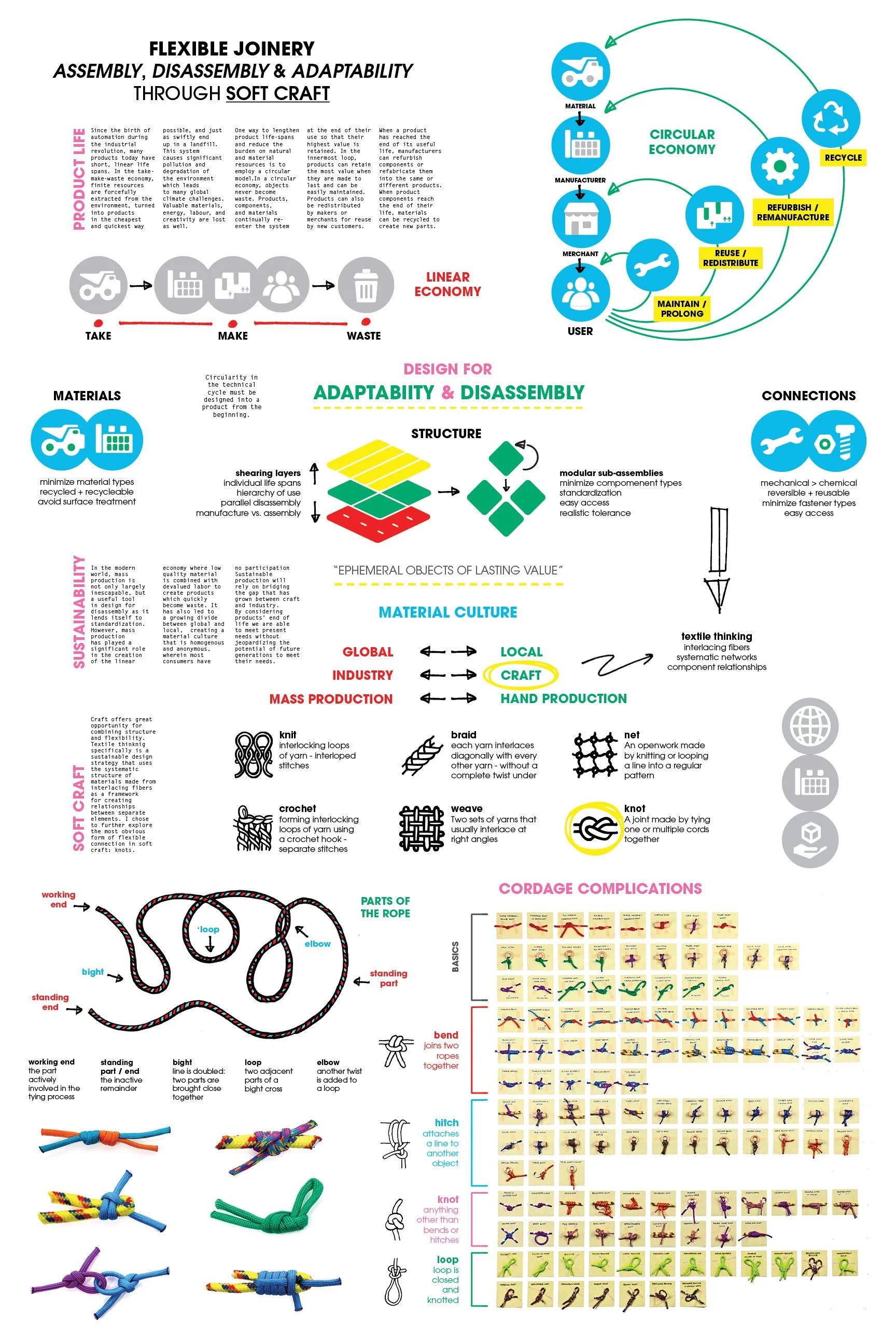

PRODUCT LIFE

In a linear economy, finite resources are forcefully extracted from the environment, processed and assembled with minimal cost, and just as swiftly end up in a landfill. Short product life spans lead to many global climate challenges wherein valuable materials, energy, labour, and creativity are lost.

In a circular economy, products, components, and materials continually re-enter the cycle at the end of their use to minimize waste. In the innermost loop, products can retain the most value when they are made to last and can be easily maintained. Products can also be redistributed by makers or merchants for

reuse by new customers. When a product has reached the end of its useful life, manufacturers can refurbish components or refabricate them into the same or different products. When individual components reach the end of their life, materials can be recycled to create new parts.

Circularity in the technical cycle must be designed into a product from the beginning.

MATERIALS

minimize material types

recycled + recycleable

avoid surface treatment

long life

Design for Adaptability & Disassembly

shearing layers

individual life spans

hierarchy of use

parallel disassembly

manufacture vs. assembly

STRUCTURE

loose fit

modular sub-assemblies

minimize compomenent types

standardization

easy access

realistic tolerance

CONNECTIONS

fastener > adhesive

mechanical > chemical

reversible + reusable

minimize fastener types

standardization

easy access

SUSTAINABILITY

Mass production has led not only to a linear economy but also a growing divide between global and local. Modern material culture that is homogenous and anonymous, wherein most consumers have no participation. Sustainable production will rely on bridging the gap craft and and automated industry which is still a necessary tool for standardization and efficiency.

“ephemeral objects of lasting value”

MATERIAL CULTURE

GLOBAL

INDUSTRY

MASS PRODUCTION

LOCAL

CRAFT

HAND PRODUCTION

TEXTILE THINKING

interlacing fibers

systematic networks

component relationships

knit

interlocking loops of yarn - interloped stitches

crochet

forming interlocking loops of yarn using a crochet hook - separate stitches

braid

each yarn interlaces diagonally with every other yarn

weave

Two sets of yarns that usually interlace at right angles

net

An openwork made by knitting or looping a line into a regular pattern

knot

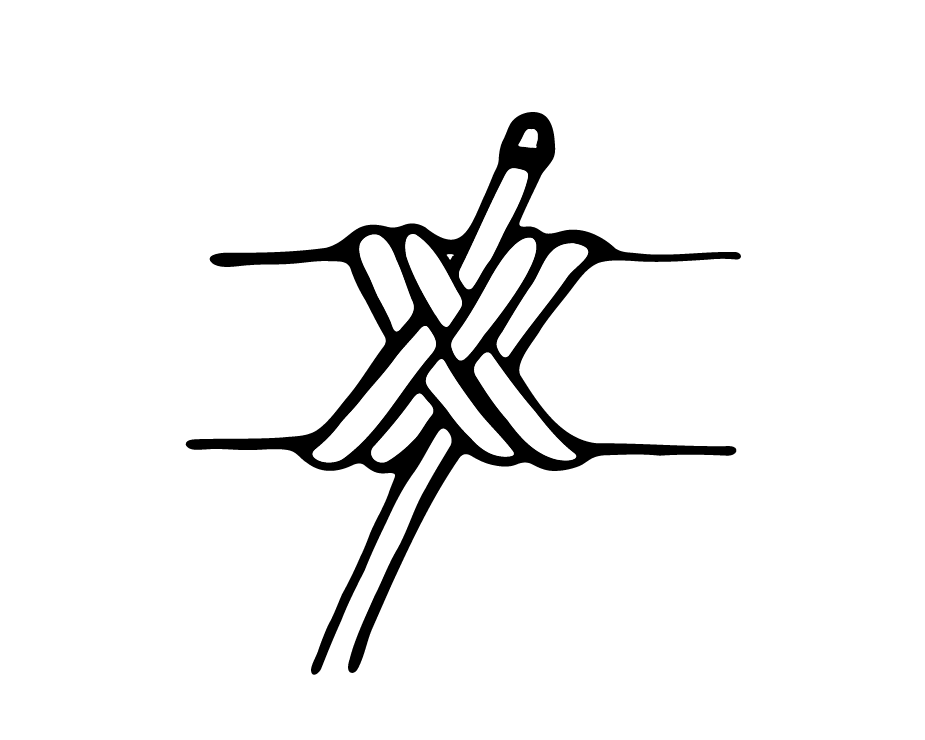

A joint made by tying one or multiple cords together

SOFT CRAFT

Many textile techniques can combine the structure and flexibility necessary for adaptable design. I chose to further explore the most obvious form of pliable connection in soft craft: knots. The same line, or cord, can be used to create various points of connection and expansive systems.

working end

the part actively involved in the tying process

standing end

the inactive remainder

bight

line is doubled - two parts are brought close together

loop

two adjacent parts of a bight cross

elbow

another twist is added to a loop

PARTS OF THE ROPE

“CORDAGE COMPLICATIONS”

I learned to tie over 120 different knots from various instructional publications. Each has unique functions, characteristics, and services in various trades.

BEND

joins two ropes together

HITCH

attaches a line to another object

KNOT

anything other than bends or hitches

LOOP

a loop is closed and knotted

IDEATION

-

IDEATION -

How might flexible joinery created through craft techniques facilitate temporary connections and act as a catalyst for assembly, disassembly, and adaptability in products which are otherwise industrially produced for singular use and a linear existence?

APPLICATION

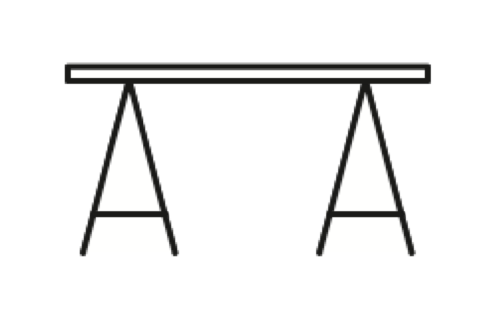

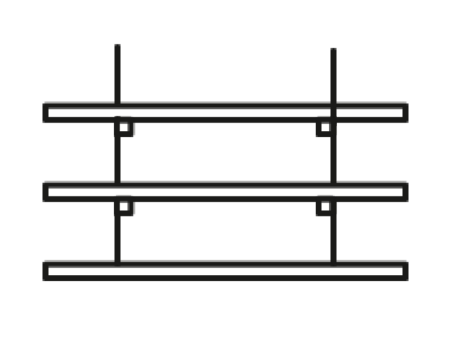

SURFACE

SEATING

STORAGE

LIGHT

ADJUST

TYPE

height

table

top

direction

floor,

standing

brightness

hanging

Anthony Incolia

Otto Kolb

Magistretti + Tedeschi

INSPIRATION

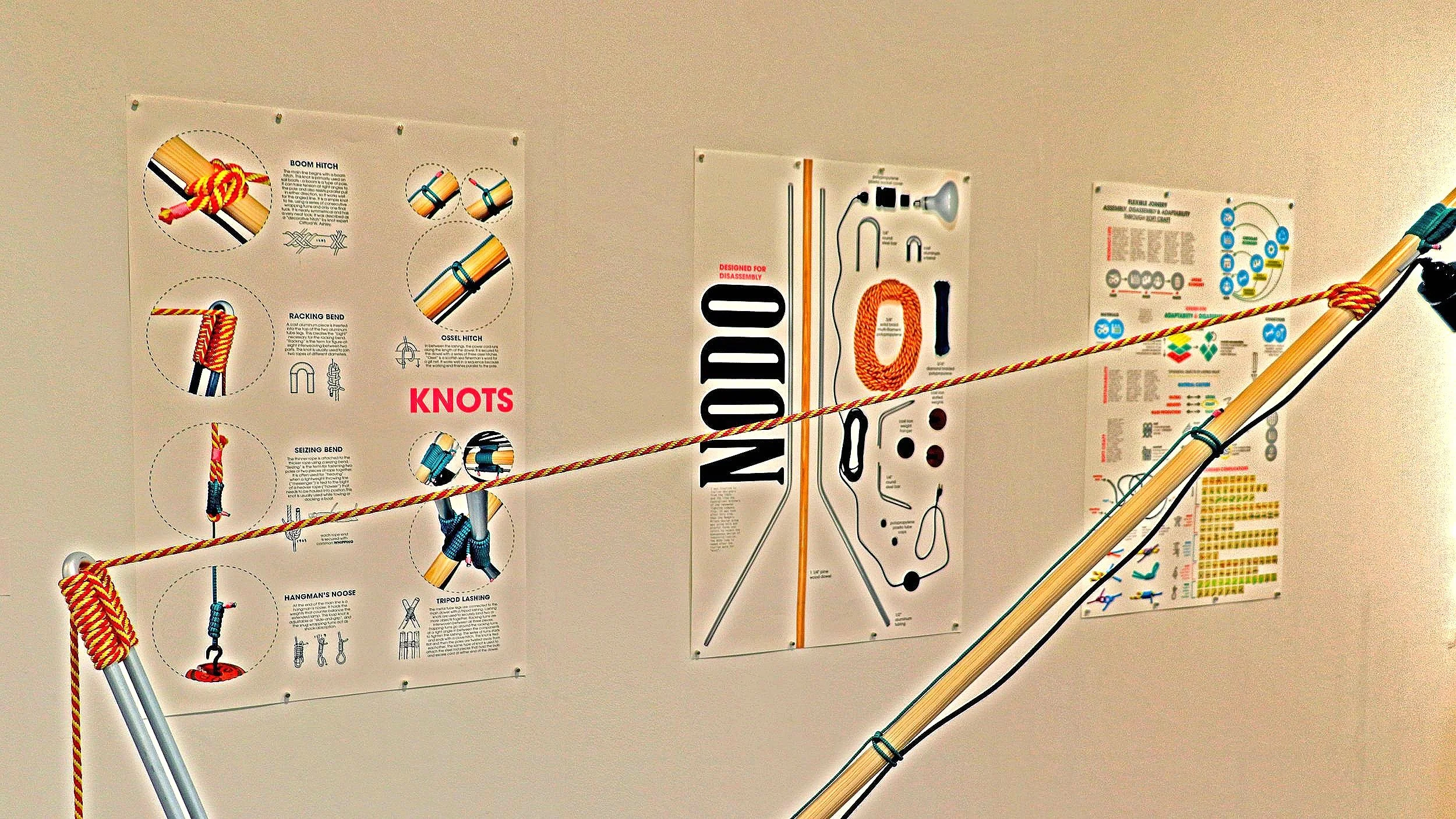

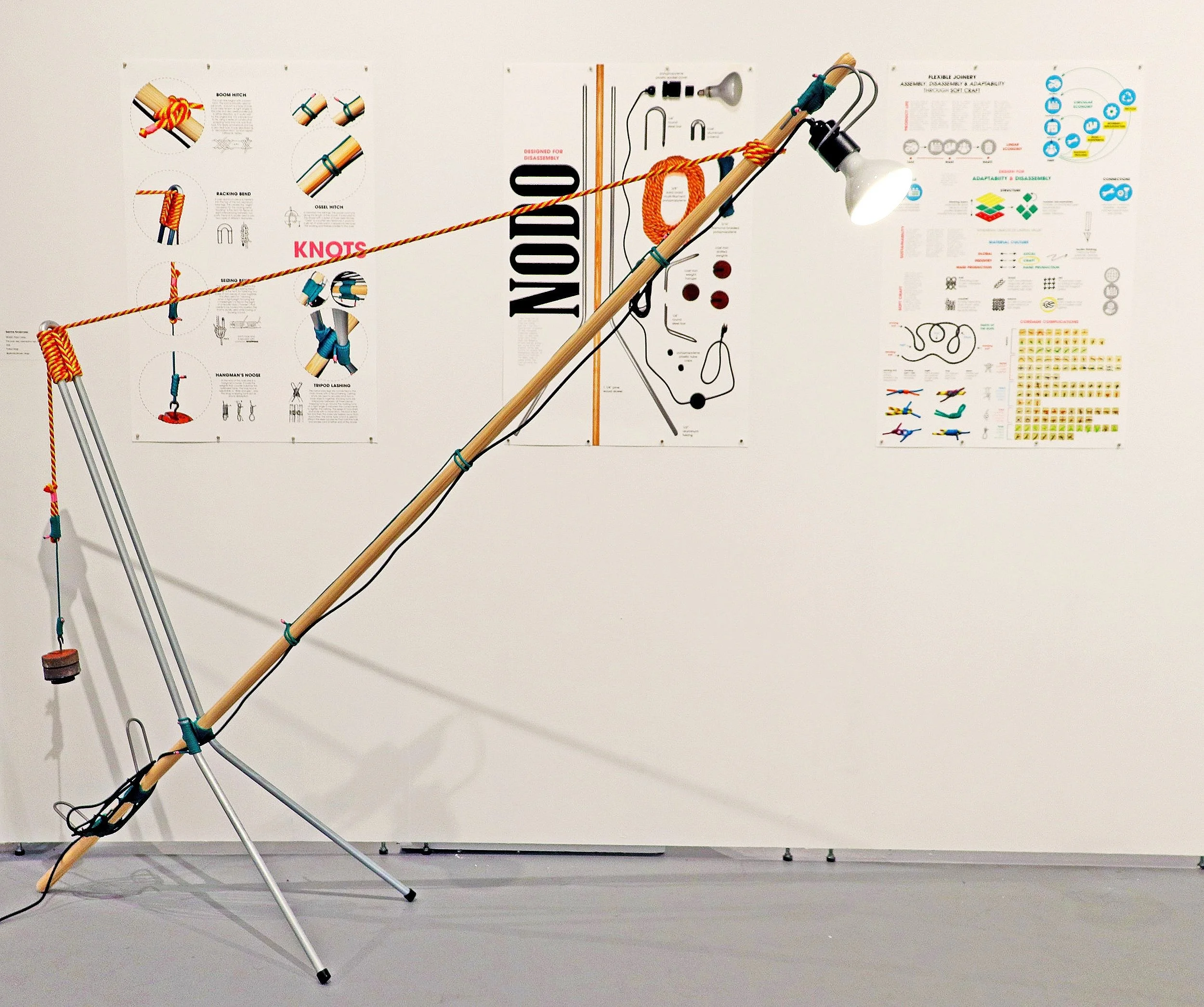

I referenced many historical examples of lighting design to consider how existing structures might be recreated using knots. I was inspired by Italian designers from the 60s and 70s like the Castiglioni brothers of Flos.

It was soon after that the Memphis design group (based in Milan) began using bold and playful forms and colors to reject the homogenous design of industrialization. These influences inspired the name “Nodo”, which is the Italian word for knot.

Achille & Pier Giacomo Castiglioni

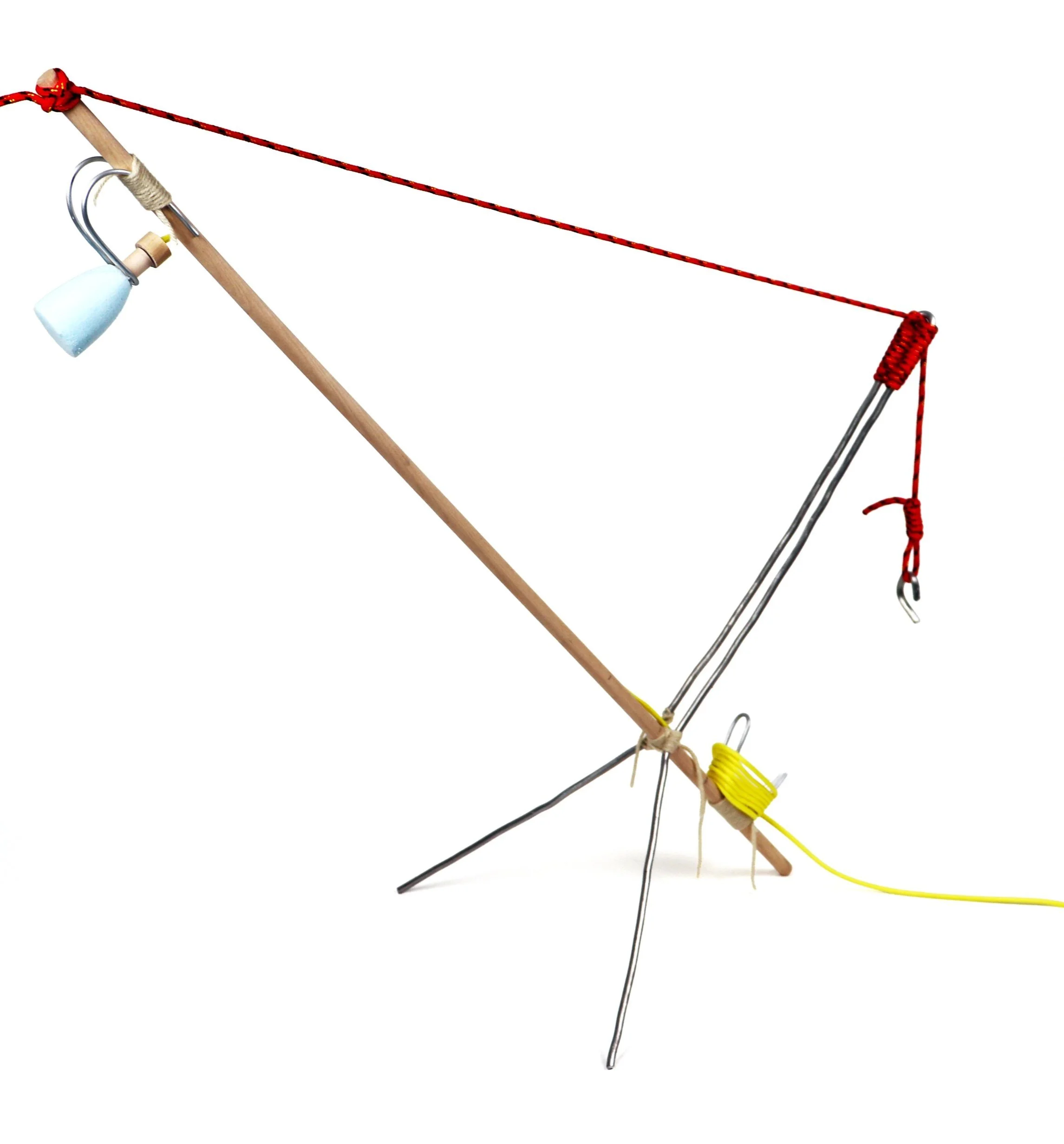

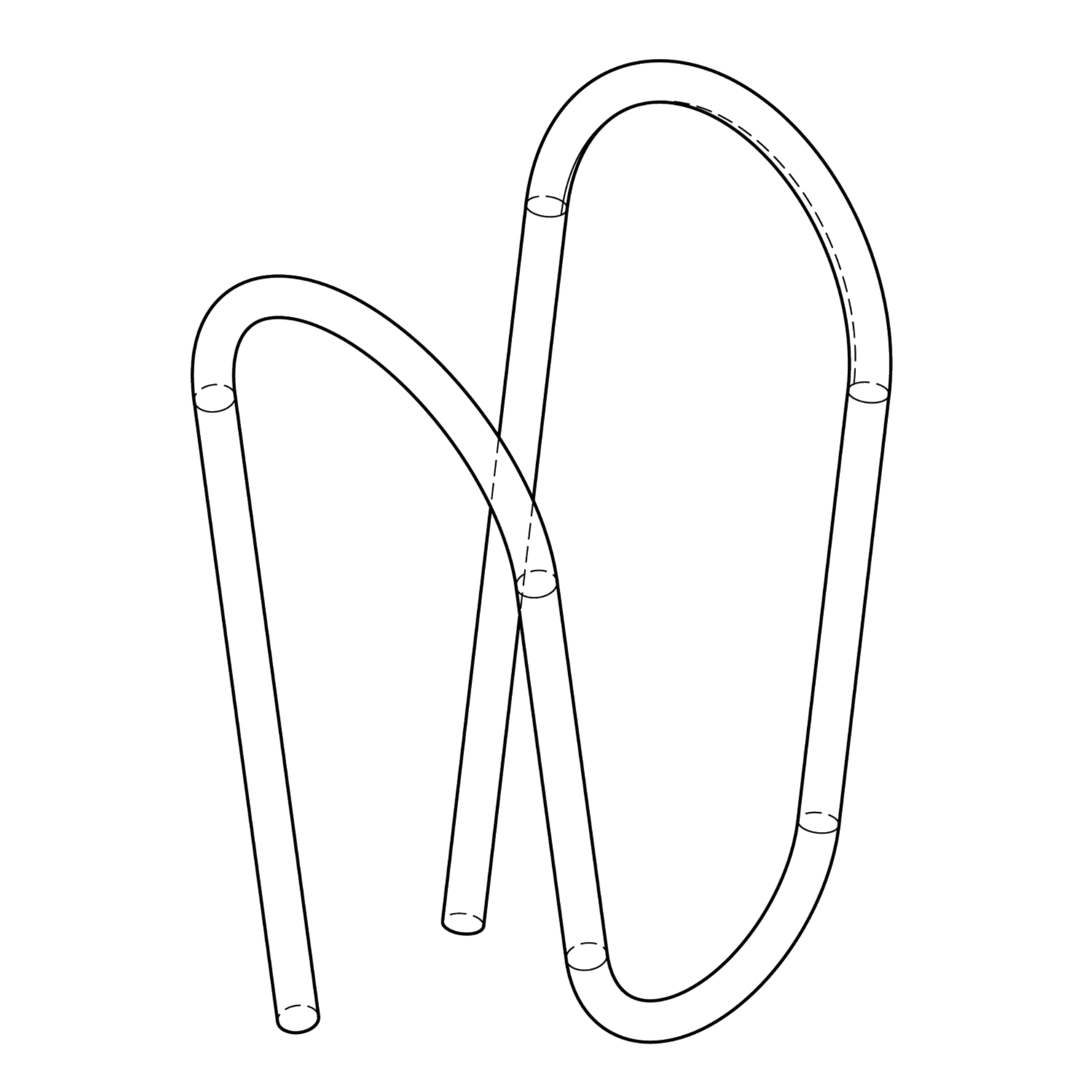

SKETCH MODELING

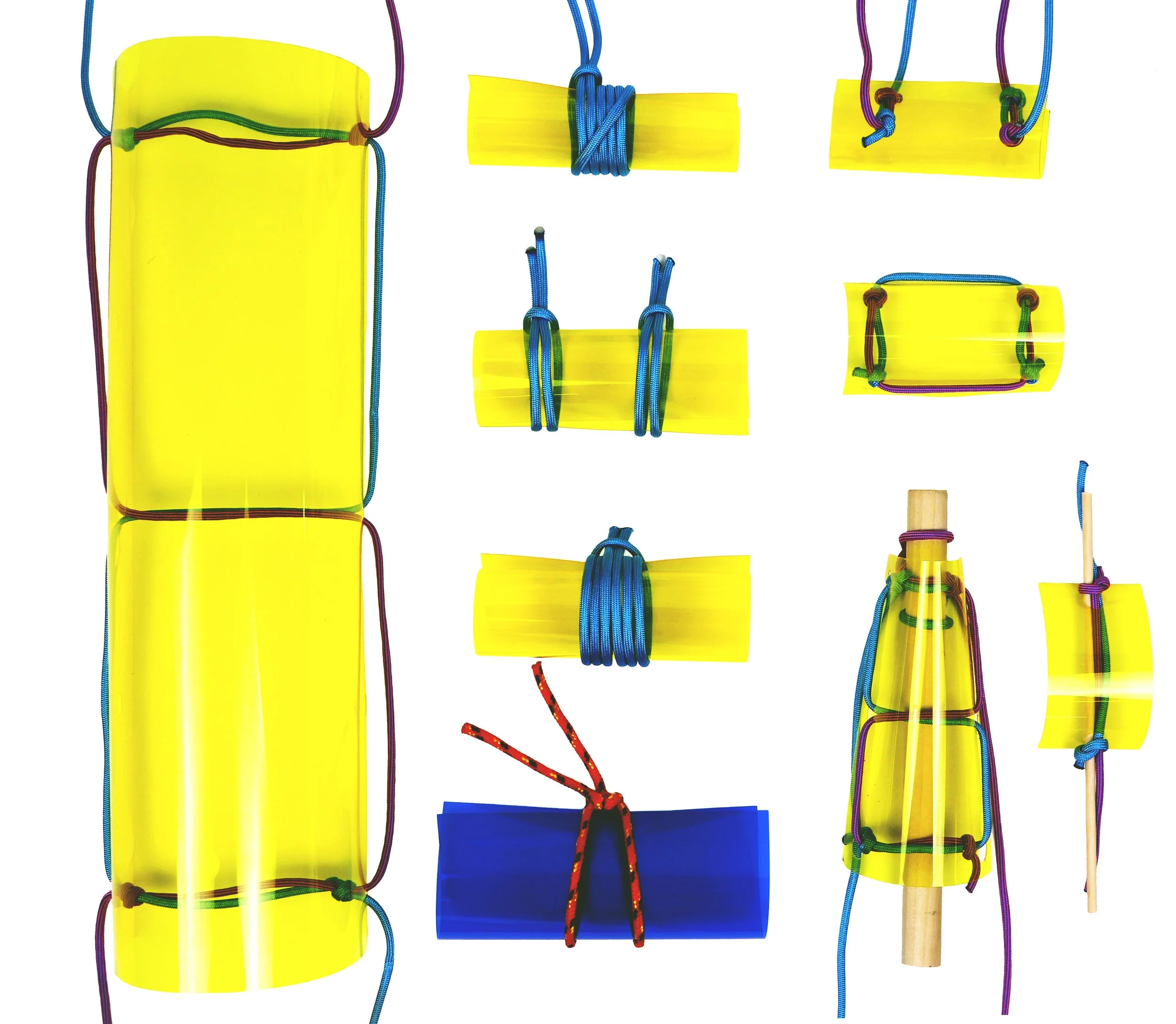

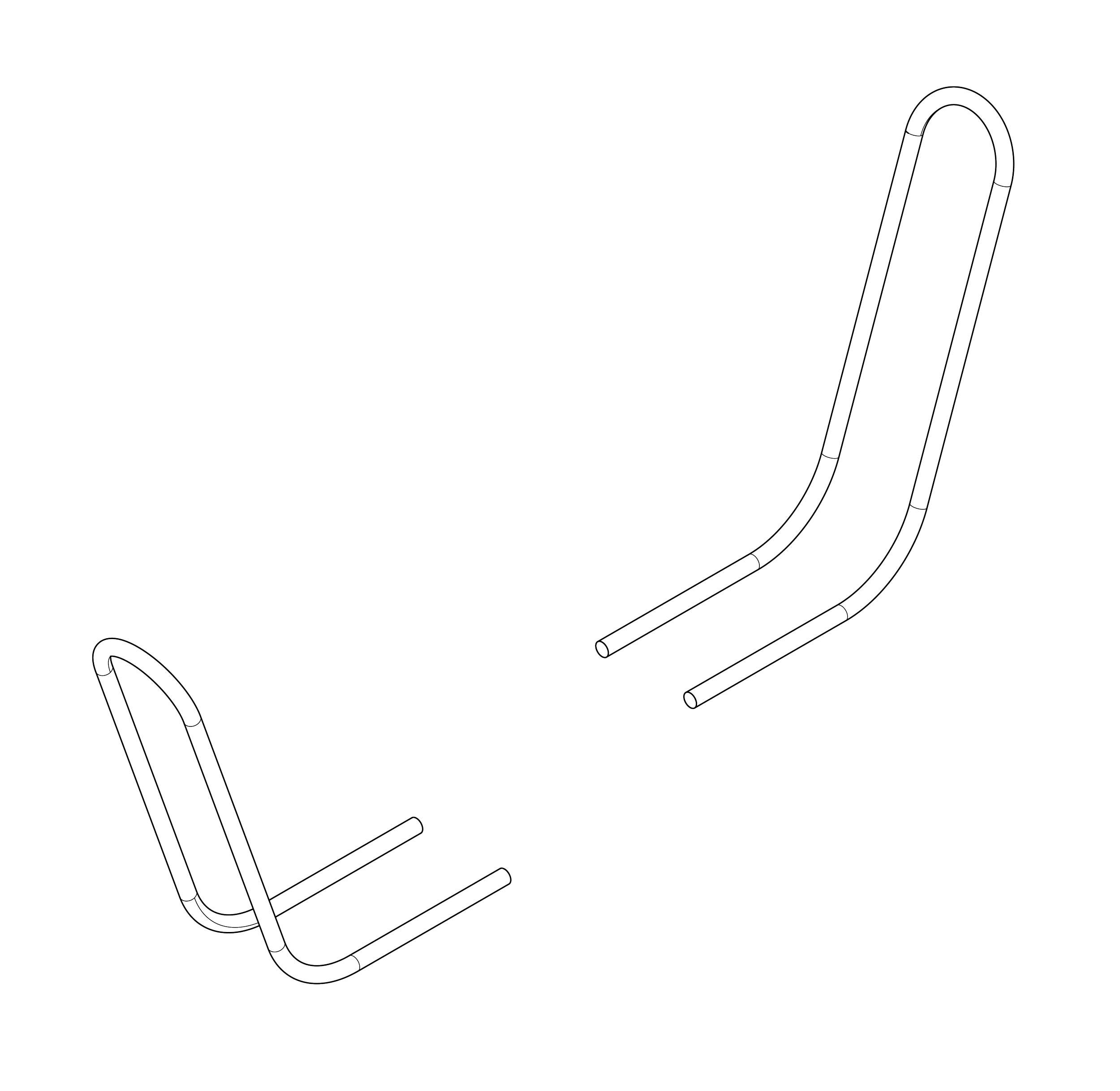

I experimented with different adjustable shade ideas and structural considerations. I decided to pursue a free-standing system that would rely on the tension of the rope and the strength of the knots to support itself. I tested many ideas where a solid u-bend component would act as the thicker cord in a knot used to join two different ropes

small-scale model

mid-scale model

full-scale testing

PROTOTYPING

As my models scaled up, I was able to test structural stability, proportions, and smaller sub-assemblies of the system including how a bulb would be integrated and where extra cord could be stored on the lamp. I tested different types and sizes of ropes from natural to synthetic fibers, and evaluated them based on their strength, ease of tie and future recyclability. I did a lot of prototyping to figure out each individual component; 3d printing socket covers and learning about metal bending tools, whose abilities and limitations would in turn also affect my design.

COMPONENTS & MATERIALS

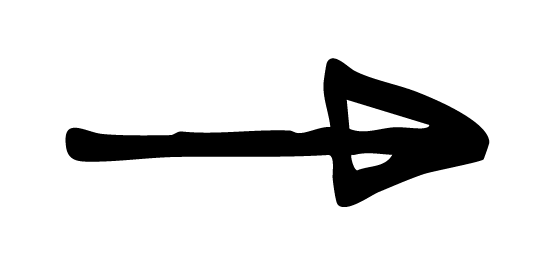

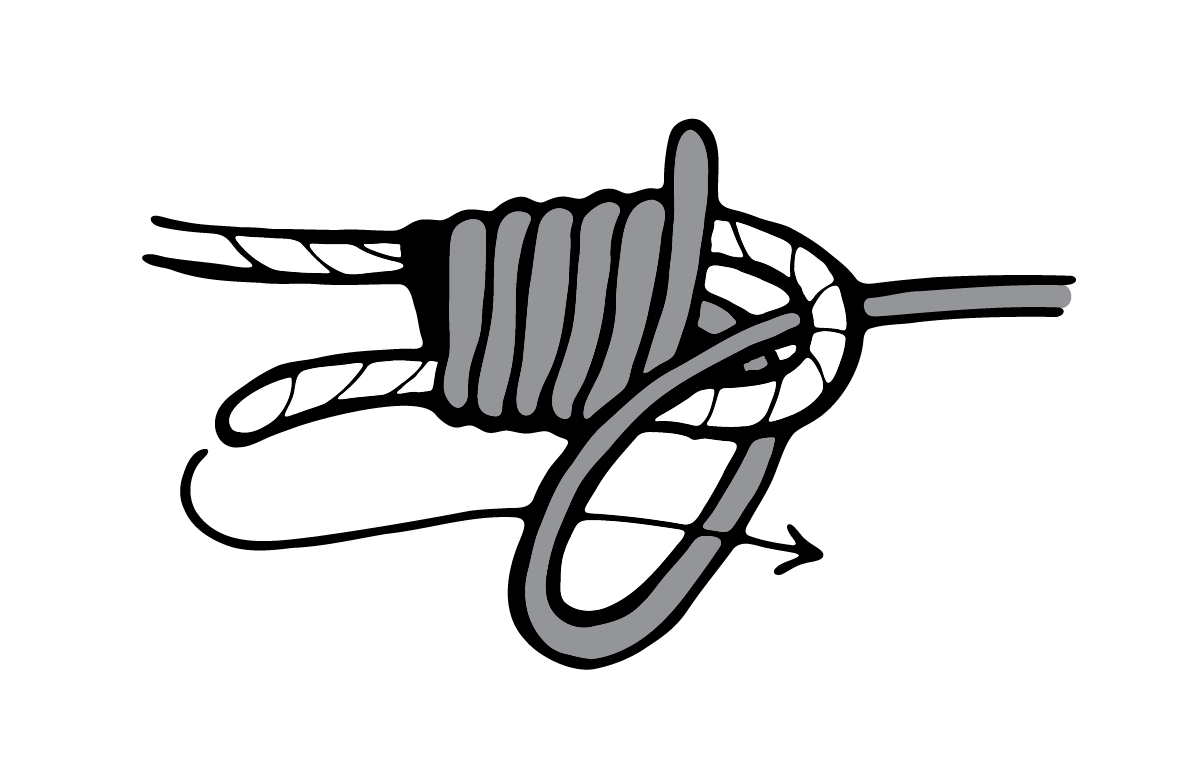

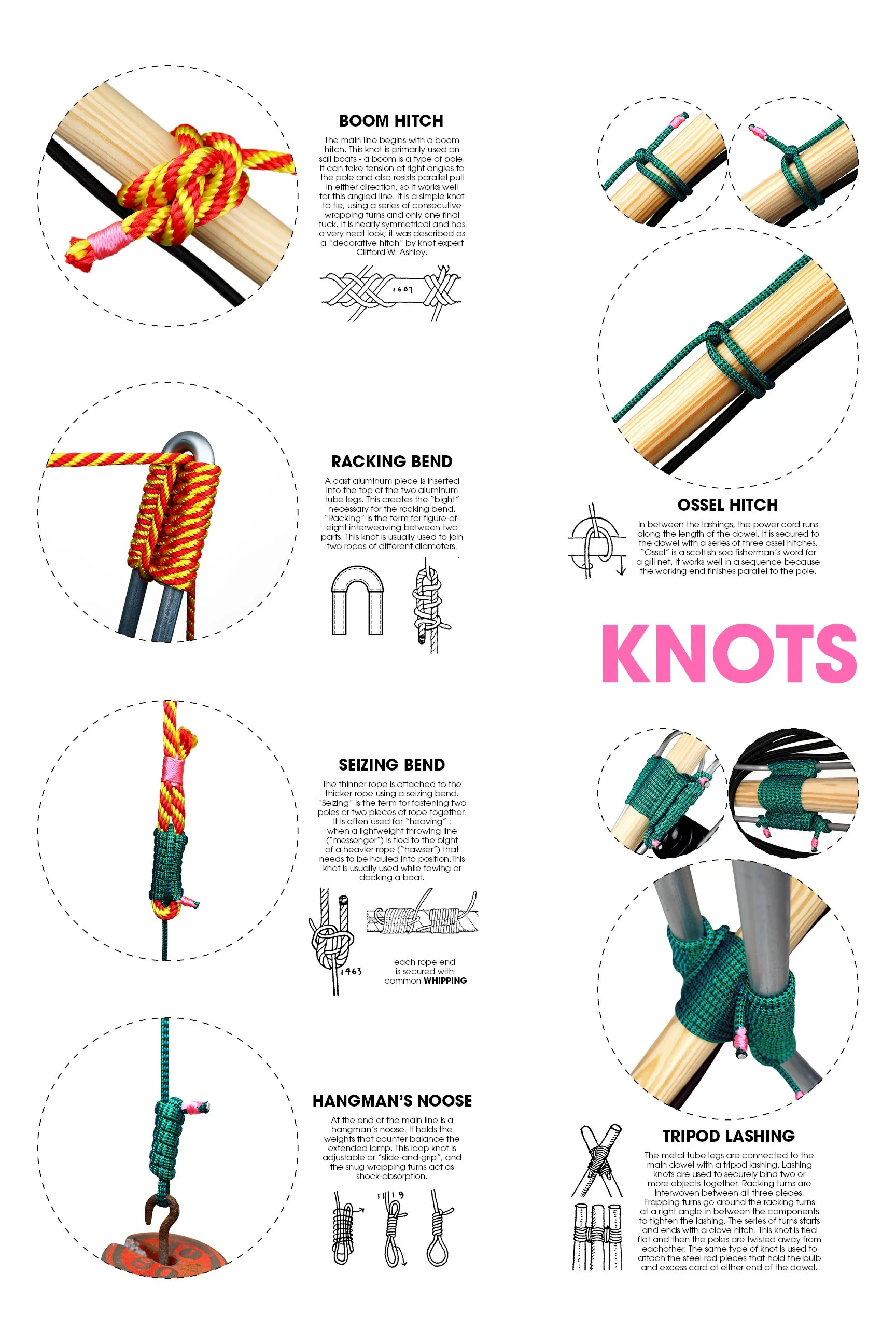

BOOM HITCH

The main line begins with a boom hitch. This knot is primarily used on sail boats - a boom is a type of pole. It can take tension at right angles to the pole and also resists parallel pull in either direction, so it works well for this angled line. It is a simple knot to tie, using a series of consecutive wrapping turns and only one final tuck. It is nearly symmetrical and has a very neat look; it was described as a “decorative hitch” by knot expert Clifford W. Ashley.

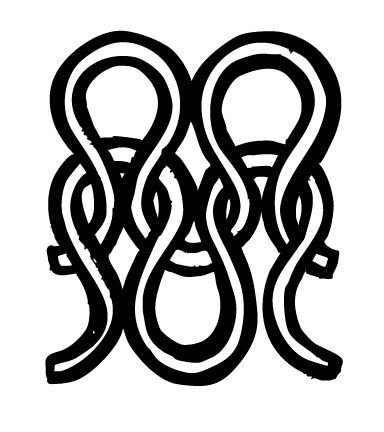

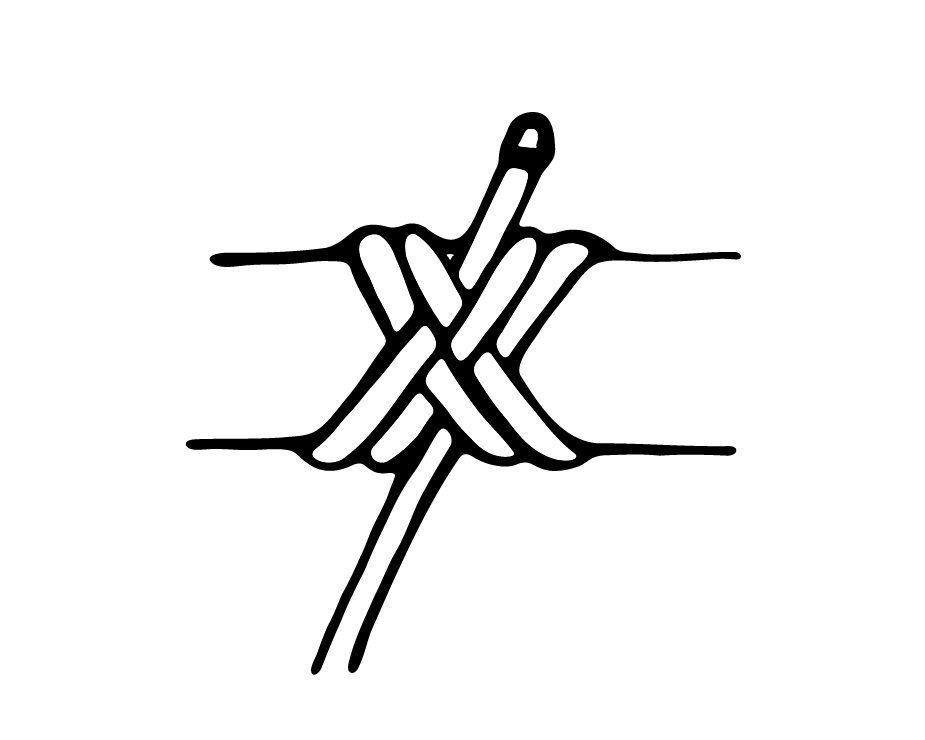

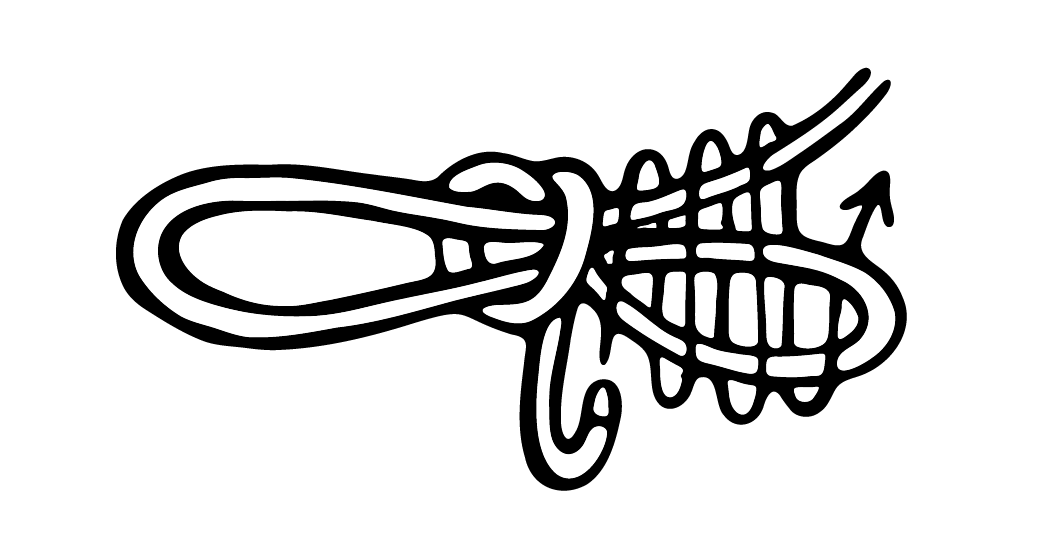

RACKING BEND

A cast aluminum piece is inserted into the top of the two aluminum tube legs. This creates the “bight” necessary for the racking bend. “Racking” is the term for figure-of-eight interweaving between two parts. This knot is usually used to join two ropes of different diameters.

SEIZING BEND

The thinner rope is attached to the thicker rope using a seizing bend. “Seizing” is the term for fastening two poles or two pieces of rope together. It is often used for “heaving” : when a lightweight throwing line (“messenger”) is tied to the bight of a heavier rope (“hawser”) that needs to be hauled into position.This knot is usually used while towing or docking a boat.

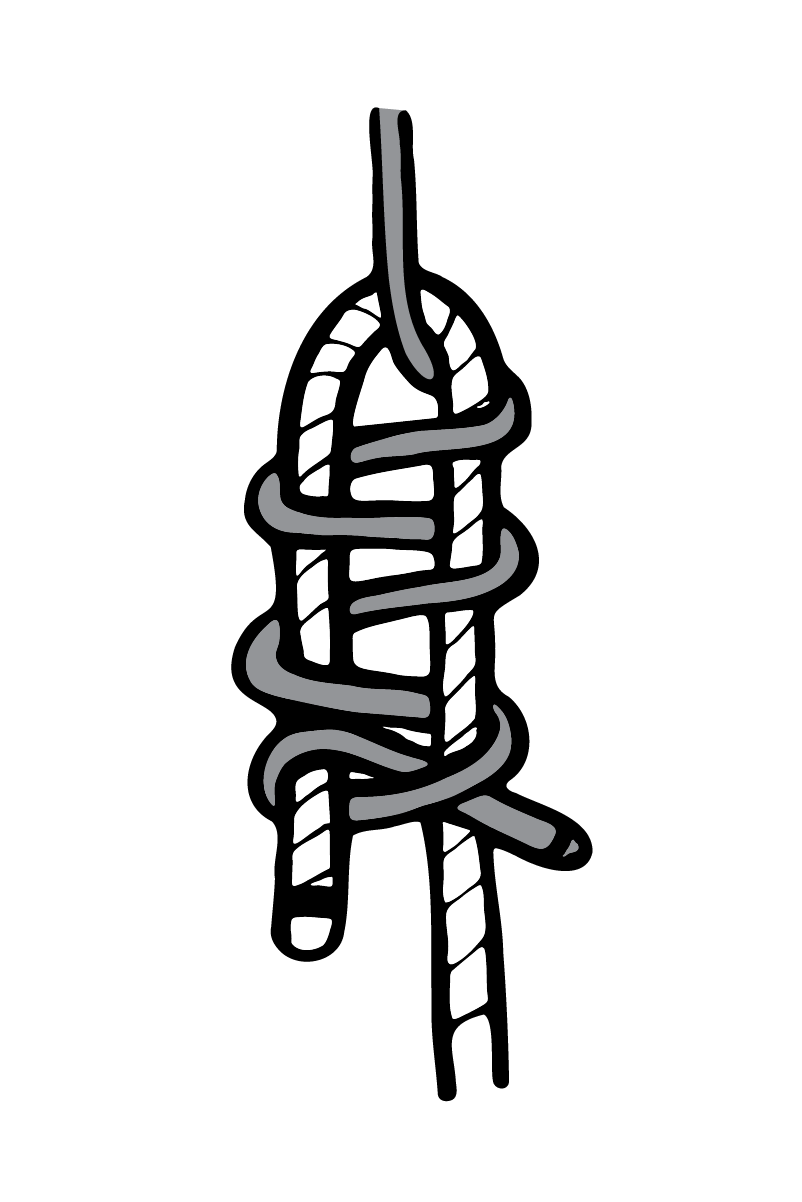

HANGMAN’S NOOSE

At the end of the main line is a hangman’s noose. It holds the weights that counter balance the extended lamp. This loop knot is adjustable or “slide-and-grip”, and the snug wrapping turns act as shock-absorption.

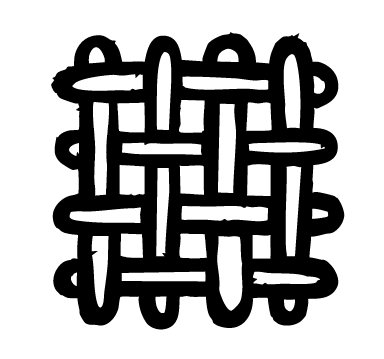

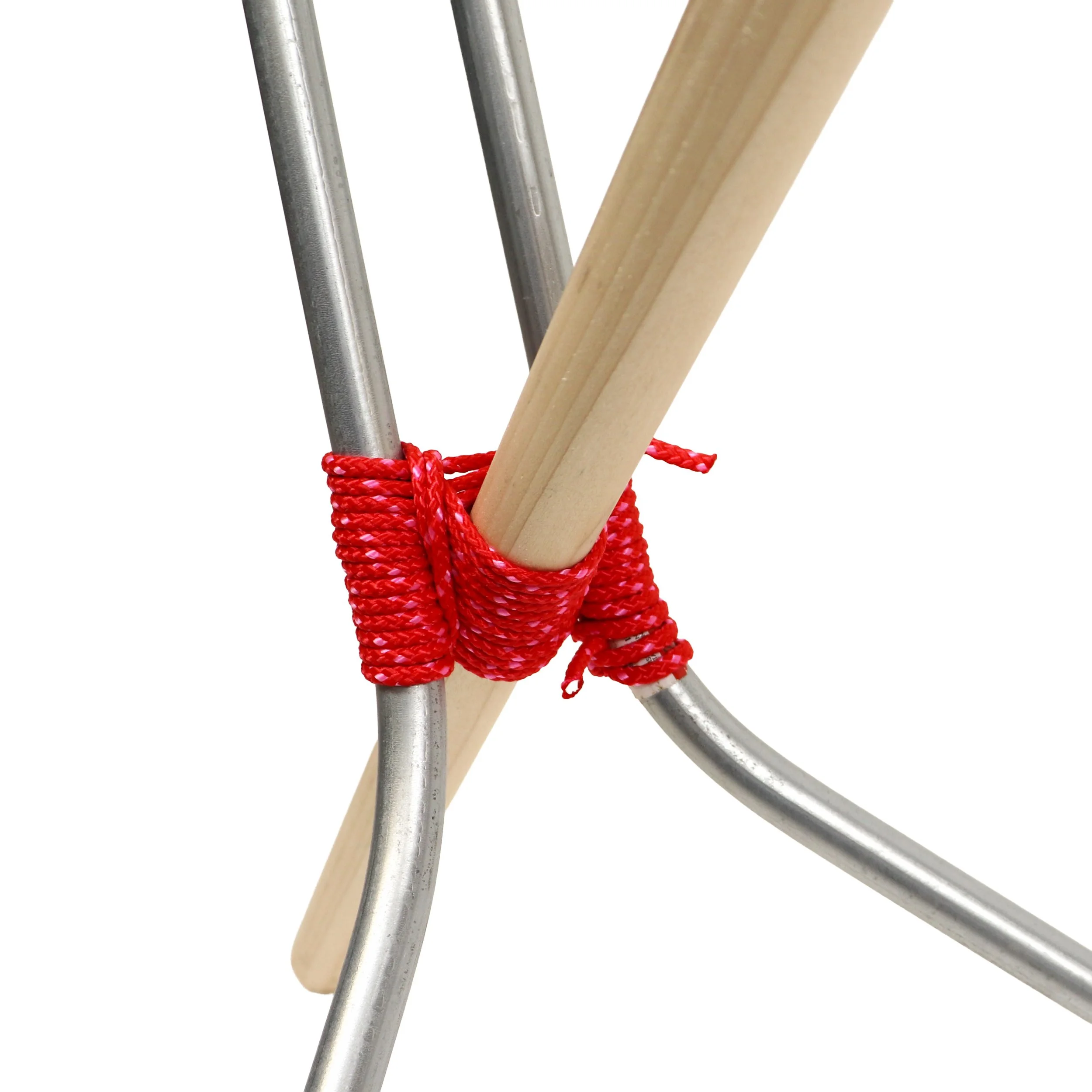

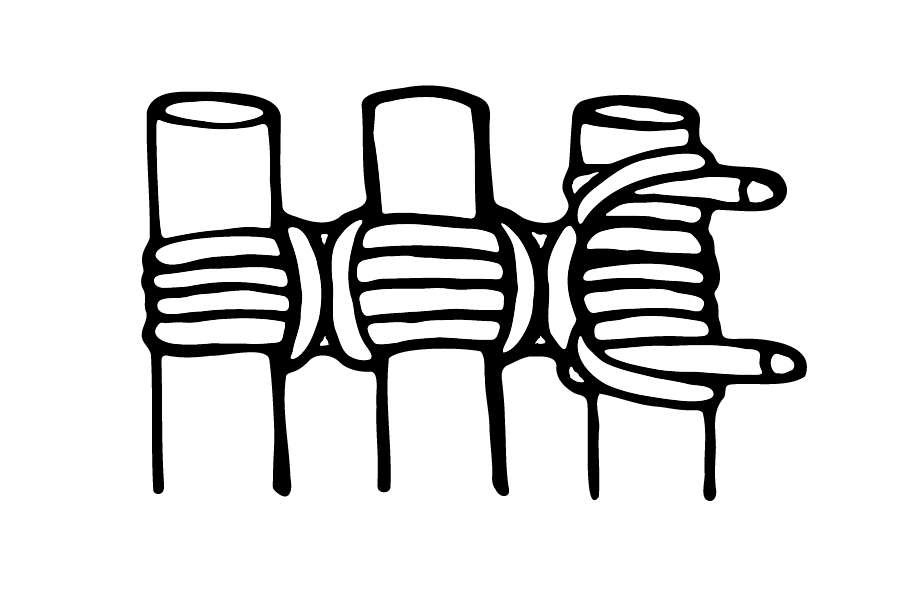

TRIPOD LASHING

The metal tube legs are connected to the main dowel with a tripod lashing. Lashing knots are used to securely bind two or more objects together. Racking turns are interwoven between all three pieces. Frapping turns go around the racking turns at a right angle in between the components to tighten the lashing. The series of turns starts and ends with a clove hitch. This knot is tied flat and then the poles are twisted away from each other.

Two identical bent steel rods form an assembly which holds the excess power cord. Both are attached to the bottom end of the dowel also with tripod lashings. The extended parts act like a cleat commonly used on boats to store rope.

A tripod lashing knot is also used to attach a bent rod to the top end of the dowel. This piece holds the bulb and socket assembly. The socket closes around a polypropylene plastic socket cover. The deep ridge sits in the center bend of the steel.

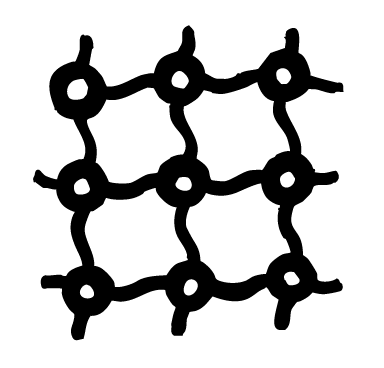

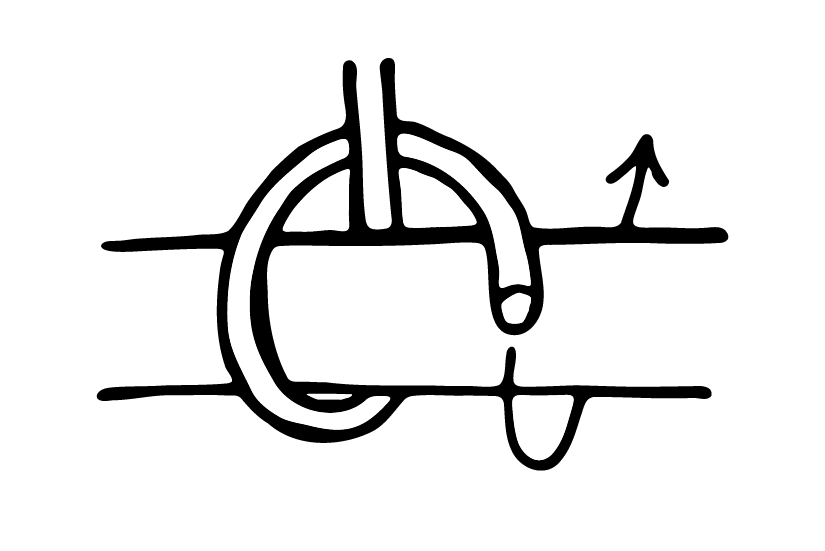

OSSEL HITCH

In between the lashings, the power cord runs along the length of the dowel. It is secured to the dowel with a series of three ossel hitches. “Ossel” is a Scottish sea fisherman’s word for a gill net. It works well in a sequence because the working end finishes parallel to the pole.